Best Manufacturing ERP Software in India

Last updated: January 22, 2026 Read in fullscreen view

- 14 Jan 2026

How to Evaluate the Business and Productivity Software Company Seismic on RFP AI Agent Use Cases 84/97

How to Evaluate the Business and Productivity Software Company Seismic on RFP AI Agent Use Cases 84/97 - 11 Dec 2025

15+ US ReactJS Companies Shaping the Future in 2026 64/122

15+ US ReactJS Companies Shaping the Future in 2026 64/122 - 19 Oct 2025

10 Best AI SDR Tools Actually Tested by Sales Teams (2026) 47/118

10 Best AI SDR Tools Actually Tested by Sales Teams (2026) 47/118 - 28 Nov 2025

Best Kentico CMS Development Practices for Agile Software Teams 39/81

Best Kentico CMS Development Practices for Agile Software Teams 39/81 - 10 Aug 2024

Odoo vs. Lark: A Comprehensive Comparison 36/796

Odoo vs. Lark: A Comprehensive Comparison 36/796 - 27 Nov 2025

10 AI Tools Every Freelancer Should Use for a Side Hustle in 2026 30/94

10 AI Tools Every Freelancer Should Use for a Side Hustle in 2026 30/94 - 21 Aug 2025

Top 30 Oldest IT Outsourcing Companies in Vietnam 26/125

Top 30 Oldest IT Outsourcing Companies in Vietnam 26/125 - 14 Aug 2024

From Steel to Software: The Reluctant Evolution of Japan's Tech Corporates 24/545

From Steel to Software: The Reluctant Evolution of Japan's Tech Corporates 24/545 - 13 Jan 2025

Why Businesses Are Choosing Microsoft Dynamics 365 Business Central Over NetSuite 14/132

Why Businesses Are Choosing Microsoft Dynamics 365 Business Central Over NetSuite 14/132 - 31 Dec 2023

Software Development Outsourcing Trends to Watch Out for in 2024 13/233

Software Development Outsourcing Trends to Watch Out for in 2024 13/233 - 23 Sep 2025

Top 10 eCommerce Website Development Companies in the USA 12/72

Top 10 eCommerce Website Development Companies in the USA 12/72 - 23 May 2022

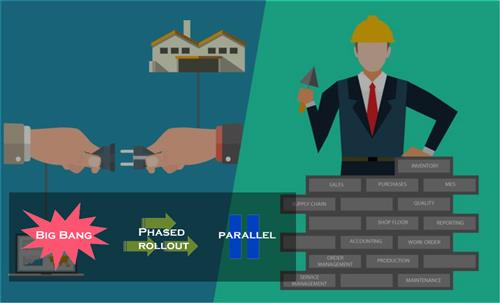

4 Strategies of Odoo ERP Implementation 12/295

4 Strategies of Odoo ERP Implementation 12/295 - 15 Jun 2022

ERP Implementation Strategies: Big Bang and Phased rollout 12/501

ERP Implementation Strategies: Big Bang and Phased rollout 12/501 - 19 Jul 2022

Odoo vs Sage Comparison 10/297

Odoo vs Sage Comparison 10/297 - 05 Aug 2024

Revisiting the Mistake That Halted Japan's Software Surge 10/342

Revisiting the Mistake That Halted Japan's Software Surge 10/342 - 16 Jan 2026

Top 10 Most Trusted Web Development Service Providers in 2026 10/27

Top 10 Most Trusted Web Development Service Providers in 2026 10/27 - 02 Sep 2024

Toolzoon Review: Features, Benefits, and Essential Tools for Enhanced Productivity 9/226

Toolzoon Review: Features, Benefits, and Essential Tools for Enhanced Productivity 9/226 - 02 Jan 2022

ERP Implementation Cost and Duration—A Tale of Two Companies (Part 2) 9/269

ERP Implementation Cost and Duration—A Tale of Two Companies (Part 2) 9/269 - 01 Jan 2022

Planning for Successful ERP Implementation Projects (Part 1) 7/216

Planning for Successful ERP Implementation Projects (Part 1) 7/216 - 03 Jan 2022

ERP System Scalability—A Tale of Two Companies (Part 3) 6/295

ERP System Scalability—A Tale of Two Companies (Part 3) 6/295 - 05 Jun 2025

Top Machine Learning Skills Employers Are Looking for in 2025 4/90

Top Machine Learning Skills Employers Are Looking for in 2025 4/90 - 15 Aug 2025

Quantum Technology: Global Challenges and Opportunities for Innovators 4/100

Quantum Technology: Global Challenges and Opportunities for Innovators 4/100 - 02 Oct 2025

Why Digital Transformation Fails: ERP Lessons, Outsourcing Strategies, and Adaptive Development Insights 3/39

Why Digital Transformation Fails: ERP Lessons, Outsourcing Strategies, and Adaptive Development Insights 3/39 - 21 Oct 2024

Simplify Your Workflow with an AI Summary Generator 3/158

Simplify Your Workflow with an AI Summary Generator 3/158 - 04 Jan 2022

Freedom of ERP Deployment Choice—A Tale of Two Companies (Part 4) 3/221

Freedom of ERP Deployment Choice—A Tale of Two Companies (Part 4) 3/221 - 23 Jan 2026

Top 10 AI Healthcare Software Development Companies in 2026 2/45

Top 10 AI Healthcare Software Development Companies in 2026 2/45

Introduction

Managing a manufacturing company today isn’t an easy task. Manufacturing managers have to manage all aspects of their business including, but not limited to, production scheduling; raw material inventories; order tracking/fulfillment processes; financial reporting; and complying with legal regulations. When they manage these tasks using traditional, paper-based and/or non-integrated business process management software tools, there is an increased chance for operational delays, mistakes and high operational costs.As such, ERP software for manufacturing is becoming increasingly critical for manufacturers across India. A manufacturing ERP (enterprise resource planning) solution combines all of the activities associated with manufacturing (including production planning, inventory management, purchasing, sales order processing, quality assurance, finance, etc.) into a single, cloud-based application to provide real-time visibility across the enterprise as well as reduce the dependence on manual processes to make decisions.

This blog post will provide an overview of manufacturing ERP software and discuss what you need to look for when selecting a manufacturing ERP system for your manufacturing business in India. In addition, we will introduce you to the Word’s first AI suite ZYNO ERP by Elite Mindz to serve the needs of today’s manufacturing industry and change the way businesses operate today.

What is Enterprise Resource Planning software?

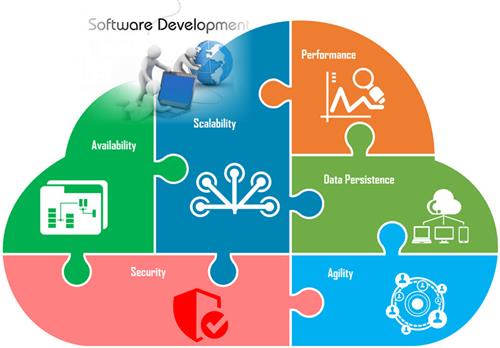

An Enterprise Resource Planning provides a single solution for integrating multiple functions within an organization (such as Finance, Purchase, Customer Service) into one software. An ERP also helps provide a comprehensive view of all business activities through real-time data and analysis, automated processes, and many features to support improved decision making and efficiency. Businesses using ERP technologies can improve productivity and reduce costs by using ERP technology to improve the way they operate their business.

Why Manufacturing Businesses Need ERP Software

Workforce Management Efficiency

The challenge of managing labor is a major issue facing manufacturers today. ERP software allows manufacturers to manage their labor resources with real-time visibility to employee attendance, shift schedules, productivity, and manufacturing performance, ensuring manufacturers can make optimal use of their human resources while reducing reliance on manual supervision.

Cost-Effective Operations

By reducing costs through automation, minimising errors and reducing losses, ERP software eliminates unnecessary costs resulting from inefficient business operations. Manufacturers can achieve higher business efficiency without having to incur additional overhead costs by establishing improved cost tracking and planning of resources.

Improved Production Scheduling

Workforce availability and production schedules synchronize through ERP systems, enabling workers to be correctly assigned to their jobs in order to reduce downtime, eliminate over-time costs, and minimize delays in production.

Reduced Operational Risks

ERP software provides a standardised workflow for an organisation which generally decreases reliance on individual employees. As such, human errors are decreased or eliminated, assisting in providing continuity in the business, while providing protection from business interruption due to unexpected events.

Better Compliance & Labor Tracking

An ERP solution provides a company with the ability to maintain accurate records of its employees' time worked, along with any necessary statutory compliance and safety requirements. In doing so, this will help reduce the possibility of legal action from employees, as well as making the conduct of audits and inspections easier and smoother.

Key Features of ERP Software for Manufacturing

1. Work Order Execution & Job Visibility

This capability allows for the centralized tracking of all production jobs within one system (including routing, operations and material status, etc.). Teams have real-time visibility of the progress of jobs using a single platform instead of through disparate systems and manual updates.

2. Capacity-Driven Production Scheduling

the scheduling of production through ERP systems is based upon information concerning ‘workforce capacity’, the availability of machines, and the preparedness of materials.This allows you to immediately adjust your production plan when priorities change or disruptions occur.

3. Real-Time Material & Stock Intelligence

Provides users with real-time information about raw materials, WIP and finished products at different sites. In addition, it automatically associates (allocates) raw materials (materials) with associated jobs in order to have the raw materials available once production has commenced.

4. Labor Monitoring & Cost Accuracy

Labor data is captured directly from ERP systems against jobs and operations and compared to estimates. This information facilitates accurate job costing and profitability analysis.

5. Order Lifecycle Coordination

ERP systems link customer orders to production schedules and inventory status, from quote through final delivery. This allows for the alignment of commitments made by a company’s sales force with what is happening on the production floor.

6. Supply Chain & Vendor Coordination

Procurement workflows are initiated as automatic responses to production-level requirements. ERP systems track purchase approvals, supplier timelines, and material availability along with production schedules.

7. Built-In Quality Assurance Controls

Qualitative reviews are an integrated portion of each phase in the manufacturing process. Digital records enable easy tracking and auditing of adherence to regulations, along with audits conducted every time a unit is produced.

8. Operational Insights & Performance Tracking

Using manufacturing ERP software allows you to create dashboards and reports that give you an overall view of the performance and efficiency of your entire manufacturing process. This enables management and employees to proactively respond to performance indicators in real-time based on the information that is being collected in the ERP system.

Obstacles when Introducing ERP Software into Business

The implementation of ERP software to support production processes is beneficial in the long run. However, implementing ERP software successfully requires significant planning, an experienced partner and being prepared by having employees ready to use the system.

1. High Initial Investment

The development of an ERP System involves high Price Tags for Licensing, Customizations, and Training, Plus Creating the Required Hardware and Software Etc.Because of these Expenses up front companies often will be reluctant to participate in an ERP Implementation.

2. Resistance to Change

As users transition from their current jobs to using an Enterprise Resource Planning (ERP) system, they will experience User Difficulty as Manual Job Duties Transitioning to ERP is a Significant Transition for Users to Deal With.

3. Data Migration Complexity

Transferring data from existing legacy systems (Generally a Spreadsheet or Other) to a New Enterprise Resource Planning (ERP) system is Not Easy and Can be Very Time Consuming and if Incorrect Pathways Are Used (Errors Made) Will Result in Major Business Issues.

4. Customization Challenges

Every manufacturing operation's workflow is different. ERP solutions that necessitate substantial customization will take longer to implement, cost more to perform, and create a more complicated system.

5. Lack of Proper Training

Employees must train to successfully use the ERP system features. Failure to provide training increases an employee's chance of making mistakes, resulting in decreased productivity and decreased use of the ERP system.

6. Integration with Existing Systems

Most manufacturers have existing software running that encompasses the areas of accounting, customer relationship management (CRM), and/or machine control. When these existing systems are not built with adequate flexibility to work with the ERP solution, integration therefore becomes particularly challenging from a technical point of view.

7. Implementation Time & Business Disruption

An ERP implementation could take months if not organized correctly. Unexpected interruptions and disruptions during the implementation of an ERP can cause problems with daily business operations, including delays in shipping products and manufacturing..

8. Choosing the Wrong ERP Partner

A manufacturer needs to ensure that they are working with an ERP supplier who understands the complexity and requirements of their industry as well as long-term customer assistance. Suppose a manufacturer chooses the wrong ERP provider. In that case, they will have difficulty receiving proper assistance during the implementation phase, and potentially not benefit from the total economic advantage of implementing the ERP.

Why ZYNO ERP Is the Best Choice for Modern Manufacturing

Modern manufacturing businesses need more than traditional software - they need an intelligent, flexible, and future-ready system. ZYNO ERP by Elite Mindz is designed to meet the real operational needs of growing manufacturers.

AI-Powered Smart Automation

ZYNO ERP utilizes AI technologies to provide intelligent automation of routine manufacturing Processes, predict demand and optimize production planning. This reduces the amount of manual labour required, improves accuracy, and allows for faster and more informed decision making on the part of the business.

Built Specifically for Manufacturing

ZYNO ERP has been designed specifically to handle manufacturing workflow processes unlike other ERP's which are generic in nature. With ZYNO ERP you can complete all aspects of production planning, inventory control, procurement, quality management and shop floor through one simple solution.

Cloud-Based & Scalable Architecture

ZYNO ERP has been developed as a cloud based manufacturing ERP software solution which will provide users with access to their data at any time from any location with very high levels of data security. ZYNO ERP is easily scalable and will grow as you need it to grow without the requirement of large amounts of infrastructure investments.

Faster Implementation & Easy Adoption

ZYNO ERP software implements high levels of usability and offers plug-and-play capabilities which allows for rapid implementation with little disruption and fast employee utilisation.

Real-Time Insights & Analytics

The ZYNO ERP Software has dashboards that provide real-time visibility of your business processes along with tools for predictive analytics through machine learning algorithms so you can take action before problems occur.

Cost-Effective & High ROI

The ZYNO ERP Software produces benefits due to reduction of waste, increased production efficiencies, and automation of core business processes, therefore providing measurable returns on investment (ROI). Its price structure is very flexible making this product among the best ERP solutions for both the Small-Medium Enterprise (SME) market in India and the Middle-Large Enterprise market in India.

Strong Support & Continuous Innovation

Backed by Elite Mindz, ZYNO ERP offers reliable support, regular updates, and continuous innovation. Businesses benefit from a long-term technology partner focused on growth and digital transformation.

Conclusion

When choosing the best ERP software in India for manufacturing businesses to enhance growth, and align business processes to stay competitive in today’s increasingly digital economy, it is important to select an ERP Software that has industry specific solutions that are scalable and offer long-term value. Therefore, when searching for the best ERP for use in the manufacturing industry, companies should consider only software that includes unique Manufacturing ERP Modules, including Production Planning, Inventory Management, Procurement Management, Financial Management and Analytic capabilities, available from a single platform.

With the new era of innovative AI-enabled software and cloud-based flexibility,World first AI Suite ZYNO ERP by Elite Mindz provides a perfect match for the evolving needs of Indian Manufacturers. As such, ZYNO delivers the necessary technology, scalability and support for success in today’s highly competitive Manufacturing environment.

Frequently Asked Question

What Does Manufacturing ERP software Do?

Manufacturing ERP software will integrate and connect every aspect of a manufacturer's business through the application of a single software solution that allows manufacturers to bring Order Fulfillment, Manufacturing, Warehousing, Purchasing and Sourcing, Sales, Accounting, HR and Payroll together into a single system to manage all aspects of their operation.

Why Should Growing Businesses Use Manufacturing ERP Software?

A Manufacturing-driven ERP System allows growing companies to manage complicated manufacturing operations by automating many of the tasks associated with running a manufacturing operation, providing tools for the control of manufacturing costs and using data generated from the ERP System to improve the effectiveness of the decision-making process.

What is the Best Manufacturing ERP Software in India?

The best Manufacturing ERP Software in India should have Manufacturing specific modules, be based on the Cloud, be scalable and have the highest level of customer support. ZYNO ERP (Elite Mindz) is a great example of an AI-enabled Manufacturing ERP system.

What are the Typical Modules of Manufacturing ERP Software?

A typical Manufacturing ERP system consists of Production Planning, Inventory/Warehouse Management, Procurement, Sales/Order Management, Quality Control, Financial Management, Reports and Analytics. Together, these Applications integrate seamlessly with ZYNO ERP.

Is Cloud Manufacturing ERP Software Better than On-Premises ERP Software?

Yes, Cloud Manufacturing ERP Systems allow for greater Flexibility, Lower Infrastructure Costs, Secure Remote Access, Automatic Updates and Easier Scalability than On-Premise ERP Systems.

Link copied!

Link copied!