The Toyota Way Management Principles

Last updated: October 21, 2025 Read in fullscreen view

- 02 Nov 2023

Unlocking Success with The Amoeba Management Model: Key Lessons, Pros & Cons, and Finding the Perfect Fit 275/889

Unlocking Success with The Amoeba Management Model: Key Lessons, Pros & Cons, and Finding the Perfect Fit 275/889 - 10 Nov 2021

5S methodology - the SECRET to Japanese SUCCESS 160/1833

5S methodology - the SECRET to Japanese SUCCESS 160/1833 - 09 Sep 2022

Kaizen, Kaikaku and Kakushin – what’s the difference? 156/3081

Kaizen, Kaikaku and Kakushin – what’s the difference? 156/3081 - 24 Nov 2022

Genba Genbutsu Genjitsu (3Gs), (Go to the Genba & see for yourself!) 136/3058

Genba Genbutsu Genjitsu (3Gs), (Go to the Genba & see for yourself!) 136/3058 - 01 Dec 2023

What is Amoeba Management? 108/1042

What is Amoeba Management? 108/1042 - 01 Apr 2022

Ishikawa (fishbone) diagram in software project management 56/3145

Ishikawa (fishbone) diagram in software project management 56/3145 - 13 Oct 2021

Outsourcing Software Development: MVP, Proof of Concept (POC) and Prototyping. Which is better? 40/486

Outsourcing Software Development: MVP, Proof of Concept (POC) and Prototyping. Which is better? 40/486 - 17 Mar 2023

Reduce waste in software development with 3M model: Muda, Mura, Muri 36/960

Reduce waste in software development with 3M model: Muda, Mura, Muri 36/960 - 09 Sep 2022

What is 5 Whys (Five Whys)? 34/970

What is 5 Whys (Five Whys)? 34/970 - 12 Dec 2024

Danshari: A Japanese Minimalist Philosophy for Cleaner Code and Leaner IT Operations 33/97

Danshari: A Japanese Minimalist Philosophy for Cleaner Code and Leaner IT Operations 33/97 - 03 Dec 2025

Templafy Features Explained: The Ultimate Guide to Streamlined Content Management 33/59

Templafy Features Explained: The Ultimate Guide to Streamlined Content Management 33/59 - 29 Jan 2026

Honne and Tatemae: Why Do Japanese People Seem Excessively Polite and Indirect? 31/40

Honne and Tatemae: Why Do Japanese People Seem Excessively Polite and Indirect? 31/40 - 12 Oct 2022

14 Common Reasons Software Projects Fail (And How To Avoid Them) 31/567

14 Common Reasons Software Projects Fail (And How To Avoid Them) 31/567 - 19 Oct 2021

Software development life cycles 29/701

Software development life cycles 29/701 - 29 Aug 2022

Difference between Kaizen and Innovation 29/910

Difference between Kaizen and Innovation 29/910 - 04 Mar 2024

Tree Ring Management: Take the Long Term View and Grow Your Business Slowly 29/444

Tree Ring Management: Take the Long Term View and Grow Your Business Slowly 29/444 - 03 Jan 2024

What is the Ringi process? 29/974

What is the Ringi process? 29/974 - 27 Aug 2022

Kaizen - Culture of Continuous Improvement and Lean Thinking 28/824

Kaizen - Culture of Continuous Improvement and Lean Thinking 28/824 - 29 Nov 2021

Memorandum of Understanding (MOU) for Partnership Agreements 28/544

Memorandum of Understanding (MOU) for Partnership Agreements 28/544 - 13 Jul 2022

Applying the business mantra "HORENSO" to Achieve 360-degree Communication 22/921

Applying the business mantra "HORENSO" to Achieve 360-degree Communication 22/921 - 15 Apr 2022

Total Quality Management (TQM) - Japanese-style management approach to quality improvement. 22/695

Total Quality Management (TQM) - Japanese-style management approach to quality improvement. 22/695 - 02 Feb 2022

Yokoten: Best Practice Sharing from a success 22/1374

Yokoten: Best Practice Sharing from a success 22/1374 - 21 Sep 2023

Abraham Wald and the Missing Bullet Holes 22/666

Abraham Wald and the Missing Bullet Holes 22/666 - 07 Mar 2023

Japan’s Unusual Farming Strategy: Renting Land and Leaving It Fallow for 5 Years — Here’s the Truth… 21/80

Japan’s Unusual Farming Strategy: Renting Land and Leaving It Fallow for 5 Years — Here’s the Truth… 21/80 - 10 Dec 2021

What is a Kano Analysis? 19/889

What is a Kano Analysis? 19/889 - 15 Jul 2022

Hansei Methodology: Continuously Engaging People in Improvement 18/707

Hansei Methodology: Continuously Engaging People in Improvement 18/707 - 04 Oct 2021

Product Validation: The Key to Developing the Best Product Possible 17/320

Product Validation: The Key to Developing the Best Product Possible 17/320 - 07 Oct 2025

Case Study: Using the “Messaging House” Framework to Build a Digital Transformation Roadmap 17/86

Case Study: Using the “Messaging House” Framework to Build a Digital Transformation Roadmap 17/86 - 05 Sep 2023

The Cold Start Problem: How to Start and Scale Network Effects 17/203

The Cold Start Problem: How to Start and Scale Network Effects 17/203 - 28 Oct 2025

The Future of Real Estate: Key Trends and Essential Lessons in Digital Transformation 16/60

The Future of Real Estate: Key Trends and Essential Lessons in Digital Transformation 16/60 - 31 Aug 2022

What are the best practices for software contract negotiations? 16/260

What are the best practices for software contract negotiations? 16/260 - 05 Mar 2021

How do you minimize risks when you outsource software development? 15/335

How do you minimize risks when you outsource software development? 15/335 - 20 Dec 2021

What is Hybrid Mobile App Development? 14/378

What is Hybrid Mobile App Development? 14/378 - 26 Sep 2024

Successful Project Management Techniques You Need to Look Out For 14/401

Successful Project Management Techniques You Need to Look Out For 14/401 - 06 Jun 2022

HEIJUNKA: The art of leveling production 13/552

HEIJUNKA: The art of leveling production 13/552 - 28 Jul 2022

POC, Prototypes, Pilots and MVP: What Are the Differences? 13/697

POC, Prototypes, Pilots and MVP: What Are the Differences? 13/697 - 19 Sep 2022

Jidoka in Software Development and Odoo ERP/MRP 12/526

Jidoka in Software Development and Odoo ERP/MRP 12/526 - 28 Oct 2022

Build Operate Transfer (B.O.T) Model in Software Outsourcing 12/405

Build Operate Transfer (B.O.T) Model in Software Outsourcing 12/405 - 07 Nov 2022

Why Design Thinking can save the outsourcing industry 12/194

Why Design Thinking can save the outsourcing industry 12/194 - 04 Oct 2022

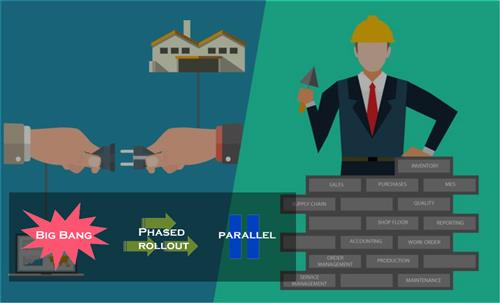

Which ERP implementation strategy is right for your business? 11/313

Which ERP implementation strategy is right for your business? 11/313 - 12 Mar 2022

The u-Japan concept 10/296

The u-Japan concept 10/296 - 01 Jan 2023

How To Use Poka-Yoke (Mistake Proofing) Technique To Improve Software Quality 10/647

How To Use Poka-Yoke (Mistake Proofing) Technique To Improve Software Quality 10/647 - 12 Dec 2021

Zero Sum Games Agile vs. Waterfall Project Management Methods 10/409

Zero Sum Games Agile vs. Waterfall Project Management Methods 10/409 - 07 Dec 2023

The Myths Of Requirements 10/256

The Myths Of Requirements 10/256 - 09 Sep 2024

How AI Rewriting Can Improve Your Content’s SEO Performance 9/188

How AI Rewriting Can Improve Your Content’s SEO Performance 9/188 - 18 Jul 2021

How To Ramp Up An Offshore Software Development Team Quickly 9/593

How To Ramp Up An Offshore Software Development Team Quickly 9/593 - 10 Nov 2021

Automated QA Outsourcing – Hire a Professional Software Testing Team 9/557

Automated QA Outsourcing – Hire a Professional Software Testing Team 9/557 - 06 Dec 2024

Steps For Integrating Sustainable Practices Into Business Operations 8/142

Steps For Integrating Sustainable Practices Into Business Operations 8/142 - 06 Mar 2024

[SemRush] What Are LSI Keywords & Why They Don‘t Matter 7/176

[SemRush] What Are LSI Keywords & Why They Don‘t Matter 7/176 - 01 Jun 2020

Japan Business Review (JBR) 7/330

Japan Business Review (JBR) 7/330 - 12 Aug 2024

Understanding Google Analytics in Mumbai: A Beginner's Guide 6/99

Understanding Google Analytics in Mumbai: A Beginner's Guide 6/99 - 01 Dec 2023

Laws of Project Management 5/302

Laws of Project Management 5/302 - 02 Apr 2022

Productivity vs. Efficiency – What Are the Differences? 4/212

Productivity vs. Efficiency – What Are the Differences? 4/212 - 12 Sep 2024

Be Water, My Friend: Fluidity, Flow & Going With the Flow 3/169

Be Water, My Friend: Fluidity, Flow & Going With the Flow 3/169 - 01 May 2024

Warren Buffett’s Golden Rule for Digital Transformation: Avoiding Tech Overload 3/205

Warren Buffett’s Golden Rule for Digital Transformation: Avoiding Tech Overload 3/205

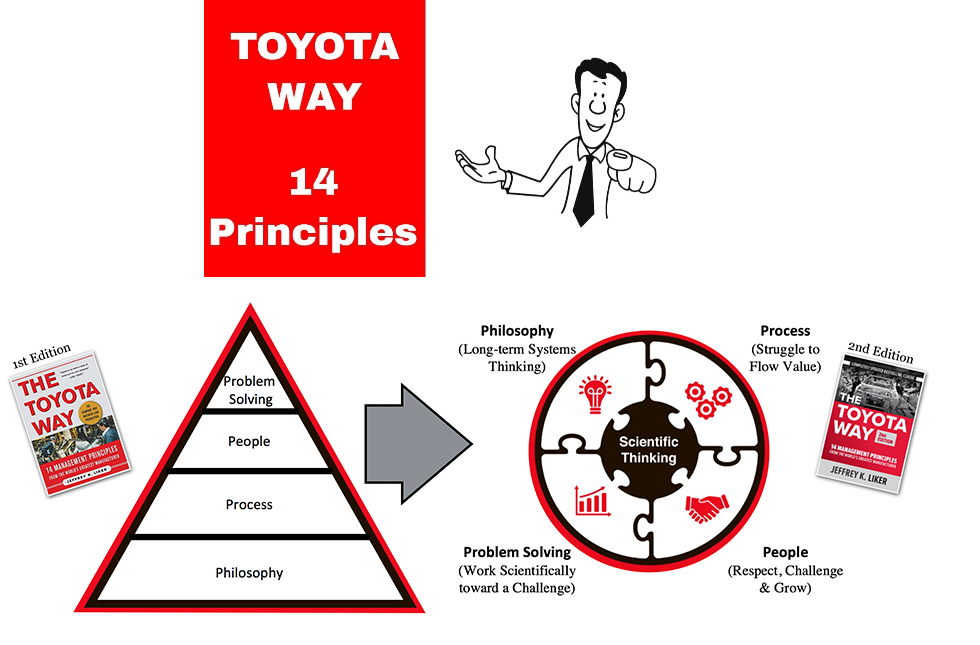

Lean principles are based largely on studies of the Toyota Production System (TPS) from the early 1980s and influence manufacturing and service organizations across the world today. Read on to learn about the Toyota Way Management Principles.

In 2001, the Toyota Motor Corporation summed up their philosophy, principles, and values in an internal document they referred to as, “the Toyota Way 2001.” The document expanded upon TPS with additional leadership and management practices that have made Toyota one of the most respected companies worldwide. Author Jeff Liker visited Toyota and summarized these principles in his 2004 book, The Toyota Way: 14 Management Principles. The book covers Toyota’s history, successes, and ideas with many great Toyota case studies. This post will focus on summarizing Toyota’s 14 Principles. How many of these principles are followed by your Lean organization?

Principle 1: Base your management decisions on a long-term philosophy, even at the expense of short-term financial goals.

Focus on doing what is right for your employees and your customer. This will lead to positive results over time. Don’t get caught up in chasing share price or short-term targets.

Principle 2: Create continuous process flow to bring problems to the surface.

Lean focuses on improvement through waste reduction. Toyota realized that striving for continuous flow forces a reduction in buffers, such as inventory and just-in-case production. A great way to identify wastes in a process is by asking the question, “what prevents this process from using a continuous process?” Write down the answers you hear as they will be wastes.

Principle 3: Use pull systems to avoid overproduction.

Only complete work in response to a signal (Kanban) if pure flow is not possible. Pull systems are typically preferable to push systems since they minimize inventory, overproduction and waste.

Principle 4: Level out the workload (heijunka).

Eliminating waste (muda) is a typical first step in Lean. However, it is critical to also even out the work (mura) and reduce overburden on the workers (muri). Heijunka is a Japanese term for the leveling of output by both volume and mix. For example, if customers have ordered 5 product A and 4 product B it would be common to produce in the sequence AAAAABBBB. Toyota would use heijunka to instead produce in the sequence ABABABABA.

Principle 5: Build a culture of stopping to fix problems, to get quality right the first time.

Toyota understands the high cost of poor quality and empowers employees to “stop the line” when they experience a problem. A signal (andon) shows leaders where the problem is so it can be addressed immediately. Note that Toyota designs their process in segments with small buffers between each segment. Most issues are corrected in the 5-10-minute buffer time and do not shut down the full line.

Principle 6: Standardized tasks are the foundation for continuous improvement and employee empowerment.

When you begin to improve a process you must agree upon a standard method. Then allow employees to try out changes that improve upon that standard. Incorporate what works into the new standard, and train coworkers on the improved process. Require that all employees use this same improved process going forward.

Principle 7: Use visual control so no problems are hidden.

Use 5S methods to standardize and optimize the work area and design simple visual systems at the place where the work is done. This will support flow and pull. For example, place a sign in a storage cabinet that shows what inventory should be located on each shelf. Another example of this principle is the A3 Improvement report, which captures an entire project on one piece of paper.

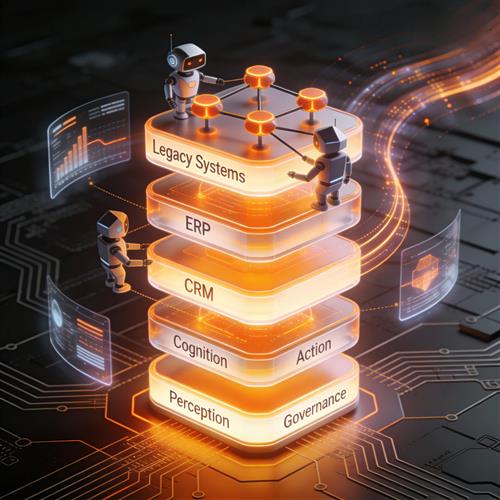

Principle 8: Use only reliable, thoroughly tested technology that serves your people and processes.

Work out a process manually before adding technology since new technology is often unreliable and difficult to standardize, therefore endangering the flow if not implemented correctly. Reject or modify technologies that conflict with your culture or that might disrupt stability, reliability, and predictability. Use technology to support people, not to replace people.

Principle 9: Grow leaders who thoroughly understand the work, live the philosophy, and teach it to others.

Grow leaders from within, rather than buying them from outside the organization. Your leaders must be role models of the organization’s philosophy and understand the daily work so that he or she can be a great teacher. These leaders will be respected and most effective.

Principle 10: Develop exceptional people and teams who follow your company’s philosophy.

Respect for people is a key pillar of the Toyota Way management principles and Lean thinking, yet many Lean organizations do not emphasize this enough. Invest in your people. Committed employees will show up and work hard at completing and improving their job every day. As Toyota trainer and author Shigeo Shingo once said, “management must learn to shift their attention from fighting fires that should not be there to developing better people and processes.”

Principle 11: Respect your extended network of partners and suppliers by challenging them and helping them improve.

Have respect for your partners and suppliers and treat them as an extension of your business. They really are when you expand your value stream map! Value them and challenge them to grow and develop. It is great to set challenging targets, but be sure to assist your partners and suppliers in achieving them.

Principle 12: Go and see for yourself to thoroughly understand the situation (genchi genbutsu).

Solve problems and improve processes by going to the source to personally observe and verify data and facts. Even high-level managers and executives should go and see things for themselves. That way they will have more than a superficial understanding of the organization’s operations.

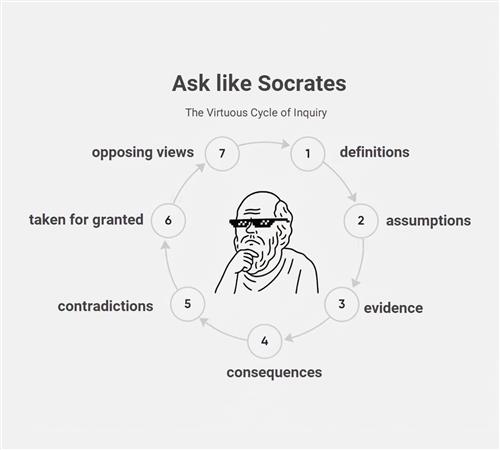

Principle 13: Make decisions slowly by consensus, thoroughly considering all options; implement decisions rapidly (nemawashi).

Nemawashi is the process of discussing problems and potential solutions with all of those affected, to collect their ideas and get an agreement on a path forward. This consensus process, though time-consuming, helps broaden the search for solutions. Once a decision is made, the stage is set for rapid implementation. This principle is like the concept Jim Collins identified in Good to Great and describes in Great by Choice of firing bullets, then cannonballs.

Principle 14: Become a learning organization through relentless reflection (hansei) and continuous improvement (kaizen).

Establish a stable process, use continuous improvement tools to determine the root cause of inefficiencies, and apply effective countermeasures. Use hansei (reflection) to openly identify all the weaknesses in your process and yourself. Now, become energized to implement countermeasures that will avoid those mistakes in the future. The goal is to develop a culture that encourages individual and team experimentation to learn what makes a process better.

Link copied!

Link copied!

Recently Updated News

Recently Updated News