Kaizen - Culture of Continuous Improvement and Lean Thinking

Last updated: October 20, 2025 Read in fullscreen view

- 02 Nov 2023

Unlocking Success with The Amoeba Management Model: Key Lessons, Pros & Cons, and Finding the Perfect Fit 275/889

Unlocking Success with The Amoeba Management Model: Key Lessons, Pros & Cons, and Finding the Perfect Fit 275/889 - 10 Nov 2021

5S methodology - the SECRET to Japanese SUCCESS 160/1833

5S methodology - the SECRET to Japanese SUCCESS 160/1833 - 09 Sep 2022

Kaizen, Kaikaku and Kakushin – what’s the difference? 156/3081

Kaizen, Kaikaku and Kakushin – what’s the difference? 156/3081 - 24 Nov 2022

Genba Genbutsu Genjitsu (3Gs), (Go to the Genba & see for yourself!) 136/3059

Genba Genbutsu Genjitsu (3Gs), (Go to the Genba & see for yourself!) 136/3059 - 01 Dec 2023

What is Amoeba Management? 108/1043

What is Amoeba Management? 108/1043 - 01 Apr 2022

Ishikawa (fishbone) diagram in software project management 56/3145

Ishikawa (fishbone) diagram in software project management 56/3145 - 10 Apr 2022

Agile self-organizing teams: What are they? How do they work? 51/535

Agile self-organizing teams: What are they? How do they work? 51/535 - 13 Oct 2021

Outsourcing Software Development: MVP, Proof of Concept (POC) and Prototyping. Which is better? 40/486

Outsourcing Software Development: MVP, Proof of Concept (POC) and Prototyping. Which is better? 40/486 - 17 Mar 2023

Reduce waste in software development with 3M model: Muda, Mura, Muri 36/960

Reduce waste in software development with 3M model: Muda, Mura, Muri 36/960 - 09 Sep 2022

What is 5 Whys (Five Whys)? 34/971

What is 5 Whys (Five Whys)? 34/971 - 21 May 2022

"Fail Fast, Fail Often, Fail Forward" is the answer to Agile practices of software success 34/1027

"Fail Fast, Fail Often, Fail Forward" is the answer to Agile practices of software success 34/1027 - 12 Dec 2024

Danshari: A Japanese Minimalist Philosophy for Cleaner Code and Leaner IT Operations 33/97

Danshari: A Japanese Minimalist Philosophy for Cleaner Code and Leaner IT Operations 33/97 - 12 Oct 2022

14 Common Reasons Software Projects Fail (And How To Avoid Them) 32/568

14 Common Reasons Software Projects Fail (And How To Avoid Them) 32/568 - 27 Oct 2020

8 principles of Agile Testing 31/1309

8 principles of Agile Testing 31/1309 - 29 Jan 2026

Honne and Tatemae: Why Do Japanese People Seem Excessively Polite and Indirect? 31/40

Honne and Tatemae: Why Do Japanese People Seem Excessively Polite and Indirect? 31/40 - 19 Oct 2021

Software development life cycles 29/701

Software development life cycles 29/701 - 29 Aug 2022

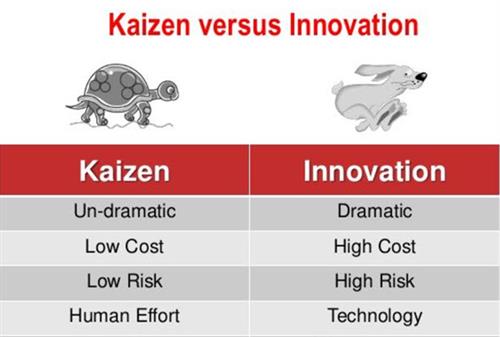

Difference between Kaizen and Innovation 29/911

Difference between Kaizen and Innovation 29/911 - 01 Mar 2022

The Toyota Way Management Principles 29/785

The Toyota Way Management Principles 29/785 - 03 Jan 2024

What is the Ringi process? 29/974

What is the Ringi process? 29/974 - 04 Mar 2024

Tree Ring Management: Take the Long Term View and Grow Your Business Slowly 29/444

Tree Ring Management: Take the Long Term View and Grow Your Business Slowly 29/444 - 07 Mar 2023

Japan’s Unusual Farming Strategy: Renting Land and Leaving It Fallow for 5 Years — Here’s the Truth… 22/81

Japan’s Unusual Farming Strategy: Renting Land and Leaving It Fallow for 5 Years — Here’s the Truth… 22/81 - 02 Feb 2022

Yokoten: Best Practice Sharing from a success 22/1374

Yokoten: Best Practice Sharing from a success 22/1374 - 13 Jul 2022

Applying the business mantra "HORENSO" to Achieve 360-degree Communication 22/921

Applying the business mantra "HORENSO" to Achieve 360-degree Communication 22/921 - 15 Apr 2022

Total Quality Management (TQM) - Japanese-style management approach to quality improvement. 22/695

Total Quality Management (TQM) - Japanese-style management approach to quality improvement. 22/695 - 12 Oct 2020

The Agile Manifesto - Principle #8 20/496

The Agile Manifesto - Principle #8 20/496 - 20 Jan 2021

Fail early, fail often, fail cheap, fail safe but always fail forward 20/750

Fail early, fail often, fail cheap, fail safe but always fail forward 20/750 - 02 Nov 2021

[Case Study] Streamlined Data Reporting using Tableau 20/309

[Case Study] Streamlined Data Reporting using Tableau 20/309 - 20 Jan 2022

TIGO Self-Organization Practice: Change Management Workflow 18/471

TIGO Self-Organization Practice: Change Management Workflow 18/471 - 15 Jul 2022

Hansei Methodology: Continuously Engaging People in Improvement 18/707

Hansei Methodology: Continuously Engaging People in Improvement 18/707 - 03 Jul 2022

Manifesto for Agile Software Development 18/276

Manifesto for Agile Software Development 18/276 - 05 Sep 2023

The Cold Start Problem: How to Start and Scale Network Effects 17/203

The Cold Start Problem: How to Start and Scale Network Effects 17/203 - 07 Oct 2025

Case Study: Using the “Messaging House” Framework to Build a Digital Transformation Roadmap 17/86

Case Study: Using the “Messaging House” Framework to Build a Digital Transformation Roadmap 17/86 - 02 Dec 2022

Success Story: Satsuki - Sales Management Software, back office app for School Subscription Management 17/248

Success Story: Satsuki - Sales Management Software, back office app for School Subscription Management 17/248 - 04 Oct 2021

Product Validation: The Key to Developing the Best Product Possible 17/320

Product Validation: The Key to Developing the Best Product Possible 17/320 - 05 Mar 2021

How do you minimize risks when you outsource software development? 16/336

How do you minimize risks when you outsource software development? 16/336 - 11 Nov 2021

What is an IT Self-service Portal? Why is it Important to Your Business? 16/427

What is an IT Self-service Portal? Why is it Important to Your Business? 16/427 - 31 Aug 2022

What are the best practices for software contract negotiations? 16/260

What are the best practices for software contract negotiations? 16/260 - 03 Sep 2022

The secret of software success: Simplicity is the ultimate sophistication 15/215

The secret of software success: Simplicity is the ultimate sophistication 15/215 - 13 Feb 2021

Why is TIGOSOFT a software house for Enterprise Application Development? 15/362

Why is TIGOSOFT a software house for Enterprise Application Development? 15/362 - 01 Jan 2024

The pros and cons of the Centralized Enterprise Automation Operating model 14/224

The pros and cons of the Centralized Enterprise Automation Operating model 14/224 - 06 Jun 2022

HEIJUNKA: The art of leveling production 13/552

HEIJUNKA: The art of leveling production 13/552 - 28 Jul 2022

POC, Prototypes, Pilots and MVP: What Are the Differences? 13/697

POC, Prototypes, Pilots and MVP: What Are the Differences? 13/697 - 19 Sep 2022

Jidoka in Software Development and Odoo ERP/MRP 12/527

Jidoka in Software Development and Odoo ERP/MRP 12/527 - 01 Mar 2022

Why Does Scrum Fail in Large Companies? 12/266

Why Does Scrum Fail in Large Companies? 12/266 - 06 Nov 2023

How do you streamline requirement analysis and modeling? 12/223

How do you streamline requirement analysis and modeling? 12/223 - 17 Jun 2021

What is IT-business alignment? 12/374

What is IT-business alignment? 12/374 - 28 Oct 2022

Build Operate Transfer (B.O.T) Model in Software Outsourcing 12/406

Build Operate Transfer (B.O.T) Model in Software Outsourcing 12/406 - 09 Oct 2022

Key Advantages and Disadvantages of Agile Methodology 11/697

Key Advantages and Disadvantages of Agile Methodology 11/697 - 07 Oct 2020

How To Manage Expectations at Work (and Why It's Important) 11/306

How To Manage Expectations at Work (and Why It's Important) 11/306 - 04 Oct 2022

Which ERP implementation strategy is right for your business? 11/313

Which ERP implementation strategy is right for your business? 11/313 - 12 Mar 2022

The u-Japan concept 10/296

The u-Japan concept 10/296 - 01 Jan 2023

How To Use Poka-Yoke (Mistake Proofing) Technique To Improve Software Quality 10/647

How To Use Poka-Yoke (Mistake Proofing) Technique To Improve Software Quality 10/647 - 16 Jun 2022

Rapid Application Development (RAD): Pros and Cons 10/867

Rapid Application Development (RAD): Pros and Cons 10/867 - 12 Dec 2021

Zero Sum Games Agile vs. Waterfall Project Management Methods 10/409

Zero Sum Games Agile vs. Waterfall Project Management Methods 10/409 - 03 Apr 2021

How digital asset management streamlines your content workflow? 9/333

How digital asset management streamlines your content workflow? 9/333 - 20 Nov 2022

Agile working method in software and football 9/344

Agile working method in software and football 9/344 - 18 Jul 2021

How To Ramp Up An Offshore Software Development Team Quickly 9/593

How To Ramp Up An Offshore Software Development Team Quickly 9/593 - 21 Oct 2022

Virtual meeting - How does TIGO save cost, reduce complexity and improve quality by remote communication? 8/191

Virtual meeting - How does TIGO save cost, reduce complexity and improve quality by remote communication? 8/191 - 16 Jul 2022

What are disadvantages of Agile Methodology? How to mitigate the disadvantages ? 8/377

What are disadvantages of Agile Methodology? How to mitigate the disadvantages ? 8/377 - 02 Nov 2022

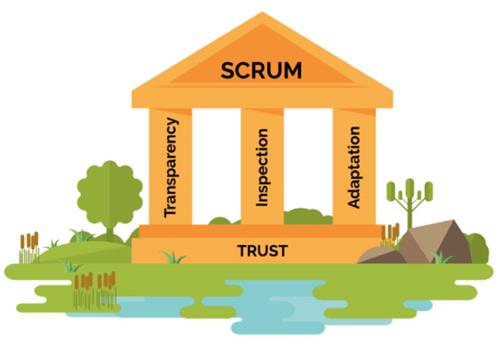

Frequently Asked Questions about Agile and Scrum 8/399

Frequently Asked Questions about Agile and Scrum 8/399 - 01 Dec 2022

Difference between Set-based development and Point-based development 8/346

Difference between Set-based development and Point-based development 8/346 - 06 Mar 2024

[SemRush] What Are LSI Keywords & Why They Don‘t Matter 7/176

[SemRush] What Are LSI Keywords & Why They Don‘t Matter 7/176 - 01 Jun 2020

Japan Business Review (JBR) 7/330

Japan Business Review (JBR) 7/330 - 01 Jun 2022

How Your Agile Development Team is Just Like a Football Team? 7/224

How Your Agile Development Team is Just Like a Football Team? 7/224 - 10 Oct 2022

Should Your Business Go Agile? (Infographic) 6/128

Should Your Business Go Agile? (Infographic) 6/128 - 21 Jun 2021

6 Useful Tips To Streamline Business Processes and Workflows 6/528

6 Useful Tips To Streamline Business Processes and Workflows 6/528 - 12 Aug 2024

Understanding Google Analytics in Mumbai: A Beginner's Guide 6/99

Understanding Google Analytics in Mumbai: A Beginner's Guide 6/99 - 01 Dec 2023

Laws of Project Management 5/302

Laws of Project Management 5/302 - 28 Nov 2023

Scrum Team Failure — Scrum Anti-Patterns Taxonomy 5/253

Scrum Team Failure — Scrum Anti-Patterns Taxonomy 5/253 - 01 May 2024

Warren Buffett’s Golden Rule for Digital Transformation: Avoiding Tech Overload 3/205

Warren Buffett’s Golden Rule for Digital Transformation: Avoiding Tech Overload 3/205

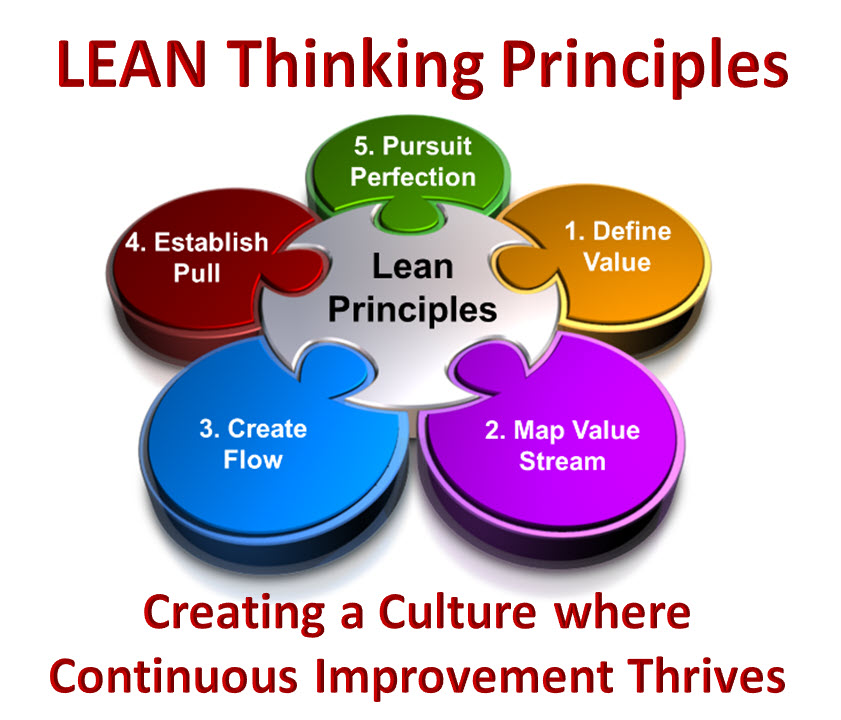

KAIZEN - RAPID IMPROVEMENT PROCESSES

Kaizen, or rapid improvement processes, often is considered to be the "building block" of all lean production methods. Kaizen focuses on eliminating waste, improving productivity, and achieving sustained continual improvement in targeted activities and processes of an organization.

Read on: Lean software development - the game-changer in the digital age

Lean production is founded on the idea of kaizen – or continual improvement. This philosophy implies that small, incremental changes routinely applied and sustained over a long period result in significant improvements. The kaizen strategy aims to involve workers from multiple functions and levels in the organization in working together to address a problem or improve a process. The team uses analytical techniques, such as value stream mapping and "the 5 whys", to identify opportunities quickly to eliminate waste in a targeted process or production area. The team works to implement chosen improvements rapidly (often within 72 hours of initiating the kaizen event), typically focusing on solutions that do not involve large capital outlays.

Also Read: Kaizen and DMAIC: What's the differences?

The 5 whys technique

Click on each picture to learn more about the 5 Whys

KAIZEN TYPES

KAIZEN PDCA

1981 Japanese PDCA Cycle - Plan, Do, Check, Act

In 1985 the Japanese PDCA Cycle was revised, utilizing additions from Kaoru Ishikawa.

The Japanese PDCA cycle was changed to include other things within the Plan, Do, Check, Act steps:

- Plan: Now divided into two steps - define goals and targets as wells as decide on ways to reach the end goal.

- Do: Now divided into two steps - participate in education and training as well as implement the plan.

- Check: Analyze the results to verify whether or not the plan has had the intended effect.

- Act: If the results of the cycle were not satisfactory go back to plan. If the results were satisfactory, standardize the solution.

The PDCA cycle functions a bit like the scientific method with people testing out hypotheses to see what works and then developing new procedures based on outcomes.

A key thing to remember is that these cycles are ongoing. Standards are important to have, but they aren't set in stone. Workplaces are dynamic and business conditions change, so standards must change, too.

Shewhart Cycle

In 1986, Deming revealed a modified Shewhart cycle. He confirmed that it was a revised version of the original 1950s version.

The new cyclical steps were:

- "What could be the team's most important accomplishments? What changes might be desirable? What data are available? Are new observations needed? If yes, plan a change or test. Decide how to use the observations.

- Carry out the change or test decided upon, preferably on a small scale.

- Observe the effects of the change or test.

- Study the results. What did we learn? What can we predict?

- Repeat step one, with knowledge accumulated.

- Repeat step two, and onward.

10 principles of Kaizen

Because executing Kaizen requires enabling the right mindset throughout a company, 10 principles that address the Kaizen mindset are commonly referenced as core to the philosophy. They are:

- Let go of assumptions.

- Be proactive about solving problems.

- Don't accept the status quo.

- Let go of perfectionism and take an attitude of iterative, adaptive change.

- Look for solutions as you find mistakes.

- Create an environment in which everyone feels empowered to contribute.

- Don't accept the obvious issue; instead, ask "why" five times to get to the root cause.

- Cull information and opinions from multiple people.

- Use creativity to find low-cost, small improvements.

- Never stop improving.

THE DUAL NATURE OF THE KAIZEN SYSTEM

Kaizen is part action plan and part philosophy.

- As an action plan, Kaizen is about organizing events focused on improving specific areas within the company. These events involve teams of employees at all levels, with an especially strong emphasis on involving plant floor employees.

- As a philosophy, Kaizen is about building a culture where all employees are actively engaged in suggesting and implementing improvements to the company. In truly lean companies, it becomes a natural way of thinking for both managers and plant floor employees.

Kaizen works hand-in-hand with Standardized Work. Standardized Work captures the current best practices for a process, and Kaizen aims to find improvements for those processes. Note the emphasis on current; Standardized Work is living documentation (it continually evolves through Kaizen).

KAIZEN EVENTS

A typical Kaizen event has a process that goes something like this:

- Set goals and provide any necessary background.

- Review the current state and develop a plan for improvements.

- Implement improvements.

- Review and fix what doesn’t work.

- Report results and determine any follow-up items.

This type of Kaizen process cycle is frequently referred to as PDCA (Plan, Do, Check, and Act). PDCA brings a scientific approach to making improvements:

- Plan: develop a hypothesis

- Do: run experiment

- Check: evaluate results

- Act: refine your experiment; then start a new cycle

IN SUMMARY

Kaizen can dramatically improve the efficiency and standardization of your company’s workflows, processes, and procedures. Kaizen can make a significant impact on employee engagement and culture, as well as workflow improvements. Kaizen is a way to transform the way your business works if everyone in it is committed to making positive changes at all levels of the company.

Interestingly, Kaizen as an action plan is exactly what develops Kaizen as a philosophy. When Kaizen is applied as an action plan through a consistent and sustained program of successful Kaizen events, it teaches employees to think differently about their work. In other words, consistently applying Kaizen as an action plan creates tremendous long-term value by developing the culture that is needed for truly effective continuous improvement.

Link copied!

Link copied!

Recently Updated News

Recently Updated News