Total Quality Management (TQM) - Japanese-style management approach to quality improvement.

Last updated: October 21, 2025 Read in fullscreen view

- 02 Nov 2023

Unlocking Success with The Amoeba Management Model: Key Lessons, Pros & Cons, and Finding the Perfect Fit 160/687

Unlocking Success with The Amoeba Management Model: Key Lessons, Pros & Cons, and Finding the Perfect Fit 160/687 - 10 Nov 2021

5S methodology - the SECRET to Japanese SUCCESS 134/1726

5S methodology - the SECRET to Japanese SUCCESS 134/1726 - 09 Sep 2022

Kaizen, Kaikaku and Kakushin – what’s the difference? 82/2897

Kaizen, Kaikaku and Kakushin – what’s the difference? 82/2897 - 24 Nov 2022

Genba Genbutsu Genjitsu (3Gs), (Go to the Genba & see for yourself!) 69/2904

Genba Genbutsu Genjitsu (3Gs), (Go to the Genba & see for yourself!) 69/2904 - 01 Dec 2023

What is Amoeba Management? 59/897

What is Amoeba Management? 59/897 - 01 Apr 2022

Ishikawa (fishbone) diagram in software project management 37/3034

Ishikawa (fishbone) diagram in software project management 37/3034 - 10 Apr 2022

Agile self-organizing teams: What are they? How do they work? 28/435

Agile self-organizing teams: What are they? How do they work? 28/435 - 18 Oct 2020

How to use the "Knowns" and "Unknowns" technique to manage assumptions 21/989

How to use the "Knowns" and "Unknowns" technique to manage assumptions 21/989 - 21 May 2022

"Fail Fast, Fail Often, Fail Forward" is the answer to Agile practices of software success 18/941

"Fail Fast, Fail Often, Fail Forward" is the answer to Agile practices of software success 18/941 - 17 Mar 2023

Reduce waste in software development with 3M model: Muda, Mura, Muri 17/860

Reduce waste in software development with 3M model: Muda, Mura, Muri 17/860 - 04 Mar 2024

Tree Ring Management: Take the Long Term View and Grow Your Business Slowly 15/374

Tree Ring Management: Take the Long Term View and Grow Your Business Slowly 15/374 - 27 Aug 2022

Kaizen - Culture of Continuous Improvement and Lean Thinking 13/705

Kaizen - Culture of Continuous Improvement and Lean Thinking 13/705 - 01 Oct 2020

Fail fast, learn faster with Agile methodology 13/973

Fail fast, learn faster with Agile methodology 13/973 - 02 Feb 2022

Yokoten: Best Practice Sharing from a success 12/1284

Yokoten: Best Practice Sharing from a success 12/1284 - 13 Jul 2022

Applying the business mantra "HORENSO" to Achieve 360-degree Communication 12/813

Applying the business mantra "HORENSO" to Achieve 360-degree Communication 12/813 - 09 Sep 2022

What is 5 Whys (Five Whys)? 12/861

What is 5 Whys (Five Whys)? 12/861 - 03 Jan 2024

What is the Ringi process? 12/876

What is the Ringi process? 12/876 - 12 Dec 2024

Danshari: A Japanese Minimalist Philosophy for Cleaner Code and Leaner IT Operations 10/22

Danshari: A Japanese Minimalist Philosophy for Cleaner Code and Leaner IT Operations 10/22 - 01 Mar 2022

The Toyota Way Management Principles 10/682

The Toyota Way Management Principles 10/682 - 21 Sep 2023

Abraham Wald and the Missing Bullet Holes 9/598

Abraham Wald and the Missing Bullet Holes 9/598 - 29 Aug 2022

Difference between Kaizen and Innovation 9/793

Difference between Kaizen and Innovation 9/793 - 15 Jul 2022

Hansei Methodology: Continuously Engaging People in Improvement 8/646

Hansei Methodology: Continuously Engaging People in Improvement 8/646 - 10 Nov 2022

Poor Code Indicators and How to Improve Your Code? 7/213

Poor Code Indicators and How to Improve Your Code? 7/213 - 19 Oct 2021

Is gold plating good or bad in project management? 7/754

Is gold plating good or bad in project management? 7/754 - 06 Feb 2021

Why fail fast and learn fast? 6/375

Why fail fast and learn fast? 6/375 - 10 Dec 2021

What is a Kano Analysis? 6/810

What is a Kano Analysis? 6/810 - 01 Mar 2023

Bug Prioritization - What are the 5 levels of priority? 6/207

Bug Prioritization - What are the 5 levels of priority? 6/207 - 19 Sep 2022

Jidoka in Software Development and Odoo ERP/MRP 5/466

Jidoka in Software Development and Odoo ERP/MRP 5/466 - 20 Nov 2022

Agile working method in software and football 5/323

Agile working method in software and football 5/323 - 06 Jun 2022

HEIJUNKA: The art of leveling production 4/481

HEIJUNKA: The art of leveling production 4/481 - 14 Oct 2021

Advantages and Disadvantages of Time and Material Contract (T&M) 4/789

Advantages and Disadvantages of Time and Material Contract (T&M) 4/789 - 08 Oct 2022

KPI - The New Leadership 3/557

KPI - The New Leadership 3/557 - 31 Oct 2021

Tips to Fail Fast With Outsourcing 3/375

Tips to Fail Fast With Outsourcing 3/375 - 18 Aug 2022

What are the consequences of poor requirements with software development projects? 3/242

What are the consequences of poor requirements with software development projects? 3/242 - 03 Jul 2022

Manifesto for Agile Software Development 2/240

Manifesto for Agile Software Development 2/240 - 26 Sep 2024

Successful Project Management Techniques You Need to Look Out For 2/368

Successful Project Management Techniques You Need to Look Out For 2/368 - 07 Mar 2023

Japan’s Unusual Farming Strategy: Renting Land and Leaving It Fallow for 5 Years — Here’s the Truth… 2/31

Japan’s Unusual Farming Strategy: Renting Land and Leaving It Fallow for 5 Years — Here’s the Truth… 2/31 - 07 Dec 2023

The Myths Of Requirements 2/203

The Myths Of Requirements 2/203 - 10 Dec 2023

Pain points of User Acceptance Testing (UAT) 2/416

Pain points of User Acceptance Testing (UAT) 2/416 - 28 Dec 2021

8 types of pricing models in software development outsourcing 2/417

8 types of pricing models in software development outsourcing 2/417 - 01 Jan 2023

How To Use Poka-Yoke (Mistake Proofing) Technique To Improve Software Quality 2/589

How To Use Poka-Yoke (Mistake Proofing) Technique To Improve Software Quality 2/589 - 23 Sep 2021

INFOGRAPHIC: Top 9 Software Outsourcing Mistakes 2/411

INFOGRAPHIC: Top 9 Software Outsourcing Mistakes 2/411 - 13 Dec 2020

Move fast, fail fast, fail-safe 2/292

Move fast, fail fast, fail-safe 2/292 - 12 Oct 2020

The Agile Manifesto - Principle #8 2/447

The Agile Manifesto - Principle #8 2/447 - 07 Oct 2020

How To Manage Expectations at Work (and Why It's Important) 2/266

How To Manage Expectations at Work (and Why It's Important) 2/266 - 17 Feb 2022

Prioritizing Software Requirements with Kano Analysis 2/280

Prioritizing Software Requirements with Kano Analysis 2/280 - 19 Apr 2021

7 Most Common Time-Wasters For Software Development 1/525

7 Most Common Time-Wasters For Software Development 1/525 - 26 Dec 2023

Improving Meeting Effectiveness Through the Six Thinking Hats 1/205

Improving Meeting Effectiveness Through the Six Thinking Hats 1/205 - 05 Jan 2024

Easy ASANA tips & tricks for you and your team 1/180

Easy ASANA tips & tricks for you and your team 1/180 - 11 Jan 2024

What are the Benefits and Limitations of Augmented Intelligence? 1/434

What are the Benefits and Limitations of Augmented Intelligence? 1/434 - 14 Mar 2024

Why should you opt for software localization from a professional agency? /117

Why should you opt for software localization from a professional agency? /117 - 12 Mar 2024

How do you create FOMO in software prospects? /127

How do you create FOMO in software prospects? /127 - 09 Sep 2024

How AI Rewriting Can Improve Your Content’s SEO Performance /140

How AI Rewriting Can Improve Your Content’s SEO Performance /140 - 12 Sep 2024

Be Water, My Friend: Fluidity, Flow & Going With the Flow /149

Be Water, My Friend: Fluidity, Flow & Going With the Flow /149 - 01 Dec 2022

Difference between Set-based development and Point-based development /298

Difference between Set-based development and Point-based development /298 - 12 Mar 2022

The u-Japan concept /234

The u-Japan concept /234 - 28 Nov 2023

Scrum Team Failure — Scrum Anti-Patterns Taxonomy (3) /228

Scrum Team Failure — Scrum Anti-Patterns Taxonomy (3) /228 - 01 Mar 2022

Why Does Scrum Fail in Large Companies? /243

Why Does Scrum Fail in Large Companies? /243 - 27 Oct 2020

8 principles of Agile Testing /1196

8 principles of Agile Testing /1196 - 21 Oct 2022

Virtual meeting - How does TIGO save cost, reduce complexity and improve quality by remote communication? /166

Virtual meeting - How does TIGO save cost, reduce complexity and improve quality by remote communication? /166 - 06 Nov 2019

How to Access Software Project Size? /236

How to Access Software Project Size? /236 - 10 Nov 2021

Automated QA Outsourcing – Hire a Professional Software Testing Team /514

Automated QA Outsourcing – Hire a Professional Software Testing Team /514 - 09 Oct 2022

Key Advantages and Disadvantages of Agile Methodology /666

Key Advantages and Disadvantages of Agile Methodology /666 - 10 Oct 2022

Should Your Business Go Agile? (Infographic) /108

Should Your Business Go Agile? (Infographic) /108 - 02 Nov 2022

Frequently Asked Questions about Agile and Scrum /372

Frequently Asked Questions about Agile and Scrum /372 - 16 Jul 2022

What are disadvantages of Agile Methodology? How to mitigate the disadvantages ? /353

What are disadvantages of Agile Methodology? How to mitigate the disadvantages ? /353 - 02 Apr 2022

Productivity vs. Efficiency – What Are the Differences? /196

Productivity vs. Efficiency – What Are the Differences? /196 - 01 Jun 2022

How Your Agile Development Team is Just Like a Football Team? /206

How Your Agile Development Team is Just Like a Football Team? /206 - 01 Jun 2020

Japan Business Review (JBR) /277

Japan Business Review (JBR) /277

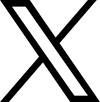

The history of total quality management (TQM) began initially as a term coined by the Naval Air Systems Command to describe its Japanese-style management approach to quality improvement. An umbrella methodology for continually improving the quality of all processes, it draws on a knowledge of the principles and practices of:

- The behavioral sciences

- The analysis of quantitative and nonquantitative data

- Economics theories

- Process analysis

During the global recession of the late ’70s and early ’80s, the United States (and the rest of the world) faced stiff competition from Japan. The Japanese had captured the world automotive and electronics markets because they found a way to produce high-quality goods at lower prices. And as a result, corporations in the U.S. looked more closely at the quality of Japanese goods and services, trying to find ways to improve production and recapture market share.

Their solution was Total Quality Management.

If your organization has just decided to incorporate TQM, or if you want to see whether this process improvement methodology can help you improve production, this blog post will cover Total Quality Management principles and techniques you can start using now.

Total Quality Management (TQM) is a management approach focusing on the improvement of quality and performance in all functions, departments, and processes across the company to provide quality services which exceed customer expectations. TQM expands the scope of quality of every department from top management to lower level employees. It enables management to adopt a strategic approach to quality and put more effort on prevention rather than on inspection. Through TQM, all employees are trained in a professional manner and encouraged to make decisions on their own to improve the overall quality and attain higher standards. This is key to achieving the TQM results desired, because without your employees on board and feeling empowered, you might as well be swimming upstream.

Through TQM, companies increase customer satisfaction, reduce costs, and foster team work. Companies can also gain higher returns on sales and investment. The ability to provide quality services allow for higher prices to be charged. Total quality means better access to global markets, greater customer loyalty, wider recognition as a quality brand, etc.

TQM is broadly based on the following principles:

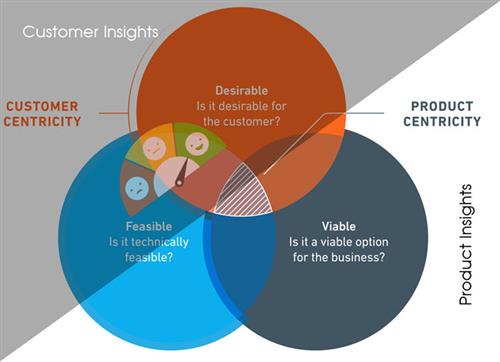

Customer Centric Approach

Consumers are the ultimate judge to determine whether products or services are of superior quality or not. No matter how many resources are pooled in training employees, upgrading machines and computers, incorporating quality design process and standards, bringing new technology, etc.; at the end of the day, it is the customers who have the final say in judging your company. Companies must remember to implement TQM across all fronts keeping in mind the customers.

Employee Involvement

Ensuring total employee involvement in achieving goals and business objectives will lead to employee empowerment and active participation from the employees in decision making and addressing quality related problems. Employee empowerment and involvement can be increased by making the workspace more open and devoid of fear.

Continual Improvement

A major component of TQM is continual improvement. Continual improvement will lead to improved and higher quality processes. Continual improvement will ensure companies will find new ways and techniques in producing better quality products, production, be more competitive, as well as exceed customer expectations.

Strategic Approach to Improvement

Businesses must adopt a strategic approach towards quality improvement to achieve their goals, vision, and mission. A strategic plan is very necessary to ensure quality becomes the core aspect of all business processes.

Integrated System

Businesses comprise of various departments with different functionality purposes. These functionalities are interconnected with various horizontal processes TQM focuses on. Everyone in the company should have a thorough understanding of the quality policies, standards, objectives, and important processes. It is very important to promote a quality work culture as it helps to achieve excellence and surpass customer expectations. An integrated system ensures continual improvement and helps companies achieve a competitive edge.

Decision Making

Data from the performance measurement of processes indicates the current health of the company. For efficient TQM, companies must collect and analyze data to improve quality, decision making accuracy, and forecasts. The decision making must be statistically and situational based in order to avoid any room for emotional based decisions.

Communications

Communication plays a crucial role in TQM as it helps to motivate employees and improve their morale during routine daily operations. Employees need to be involved as much as possible in the day to day operations and decision making process to really give them a sense of empowerment. This creates the environment of success and unity and helps drive the results the TQM process can achieve.

It requires immense efforts, time, courage, and patience to successfully implement TQM. Businesses successfully implementing TQM can witness improved quality across all major processes and departments, higher customer retention, higher revenue due to improved sales, and global brand recognition.

Link copied!

Link copied!