What is 5 Whys (Five Whys)?

Last updated: October 21, 2025 Read in fullscreen view

- 02 Nov 2023

Unlocking Success with The Amoeba Management Model: Key Lessons, Pros & Cons, and Finding the Perfect Fit 275/889

Unlocking Success with The Amoeba Management Model: Key Lessons, Pros & Cons, and Finding the Perfect Fit 275/889 - 10 Nov 2021

5S methodology - the SECRET to Japanese SUCCESS 160/1833

5S methodology - the SECRET to Japanese SUCCESS 160/1833 - 09 Sep 2022

Kaizen, Kaikaku and Kakushin – what’s the difference? 156/3081

Kaizen, Kaikaku and Kakushin – what’s the difference? 156/3081 - 24 Nov 2022

Genba Genbutsu Genjitsu (3Gs), (Go to the Genba & see for yourself!) 136/3058

Genba Genbutsu Genjitsu (3Gs), (Go to the Genba & see for yourself!) 136/3058 - 01 Dec 2023

What is Amoeba Management? 108/1042

What is Amoeba Management? 108/1042 - 01 Apr 2022

Ishikawa (fishbone) diagram in software project management 56/3145

Ishikawa (fishbone) diagram in software project management 56/3145 - 28 Oct 2023

The GOLDEN Rules of Software Engineering 47/593

The GOLDEN Rules of Software Engineering 47/593 - 18 Oct 2020

How to use the "Knowns" and "Unknowns" technique to manage assumptions 38/1089

How to use the "Knowns" and "Unknowns" technique to manage assumptions 38/1089 - 17 Mar 2023

Reduce waste in software development with 3M model: Muda, Mura, Muri 36/960

Reduce waste in software development with 3M model: Muda, Mura, Muri 36/960 - 12 Dec 2024

Danshari: A Japanese Minimalist Philosophy for Cleaner Code and Leaner IT Operations 33/97

Danshari: A Japanese Minimalist Philosophy for Cleaner Code and Leaner IT Operations 33/97 - 29 Jan 2026

Honne and Tatemae: Why Do Japanese People Seem Excessively Polite and Indirect? 31/40

Honne and Tatemae: Why Do Japanese People Seem Excessively Polite and Indirect? 31/40 - 14 Oct 2021

Stream Story - Low land stream or fast moving stream? 30/633

Stream Story - Low land stream or fast moving stream? 30/633 - 04 Mar 2024

Tree Ring Management: Take the Long Term View and Grow Your Business Slowly 29/444

Tree Ring Management: Take the Long Term View and Grow Your Business Slowly 29/444 - 29 Aug 2022

Difference between Kaizen and Innovation 29/910

Difference between Kaizen and Innovation 29/910 - 03 Jan 2024

What is the Ringi process? 29/974

What is the Ringi process? 29/974 - 27 Aug 2022

Kaizen - Culture of Continuous Improvement and Lean Thinking 28/824

Kaizen - Culture of Continuous Improvement and Lean Thinking 28/824 - 13 Oct 2021

What is Bug Convergence? Why is it important for User Acceptance Testing (UAT)? 28/759

What is Bug Convergence? Why is it important for User Acceptance Testing (UAT)? 28/759 - 01 Mar 2022

The Toyota Way Management Principles 28/784

The Toyota Way Management Principles 28/784 - 08 Dec 2021

What Are The 4 Types of Maintenance Strategies? 25/1146

What Are The 4 Types of Maintenance Strategies? 25/1146 - 01 Oct 2020

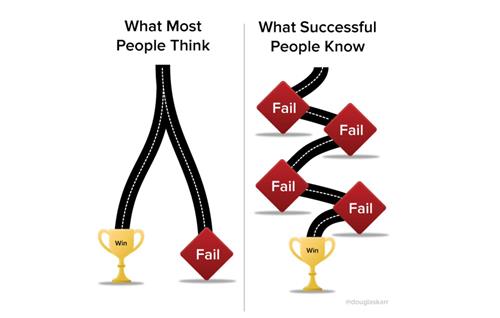

Fail fast, learn faster with Agile methodology 24/1047

Fail fast, learn faster with Agile methodology 24/1047 - 05 May 2021

TIGO Magic Scale - PoC tool for you to apply dichotomous thinking before submitting RFP 24/343

TIGO Magic Scale - PoC tool for you to apply dichotomous thinking before submitting RFP 24/343 - 13 Jul 2022

Applying the business mantra "HORENSO" to Achieve 360-degree Communication 22/921

Applying the business mantra "HORENSO" to Achieve 360-degree Communication 22/921 - 02 Feb 2022

Yokoten: Best Practice Sharing from a success 22/1374

Yokoten: Best Practice Sharing from a success 22/1374 - 14 Oct 2021

Advantages and Disadvantages of Time and Material Contract (T&M) 22/864

Advantages and Disadvantages of Time and Material Contract (T&M) 22/864 - 15 Apr 2022

Total Quality Management (TQM) - Japanese-style management approach to quality improvement. 22/695

Total Quality Management (TQM) - Japanese-style management approach to quality improvement. 22/695 - 21 Sep 2023

Abraham Wald and the Missing Bullet Holes 22/666

Abraham Wald and the Missing Bullet Holes 22/666 - 07 Mar 2023

Japan’s Unusual Farming Strategy: Renting Land and Leaving It Fallow for 5 Years — Here’s the Truth… 21/80

Japan’s Unusual Farming Strategy: Renting Land and Leaving It Fallow for 5 Years — Here’s the Truth… 21/80 - 13 May 2022

IT Training and Development: The most effective options for upskilling IT staff 21/1146

IT Training and Development: The most effective options for upskilling IT staff 21/1146 - 02 Dec 2022

3 Levels of Quality in KANO Analysis Model 21/1120

3 Levels of Quality in KANO Analysis Model 21/1120 - 13 Dec 2020

Move fast, fail fast, fail-safe 20/323

Move fast, fail fast, fail-safe 20/323 - 18 Aug 2022

What are the consequences of poor requirements with software development projects? 20/274

What are the consequences of poor requirements with software development projects? 20/274 - 06 Feb 2021

Why fail fast and learn fast? 19/450

Why fail fast and learn fast? 19/450 - 10 Dec 2021

What is a Kano Analysis? 19/889

What is a Kano Analysis? 19/889 - 15 Jul 2022

Hansei Methodology: Continuously Engaging People in Improvement 18/707

Hansei Methodology: Continuously Engaging People in Improvement 18/707 - 23 Sep 2021

INFOGRAPHIC: Top 9 Software Outsourcing Mistakes 17/439

INFOGRAPHIC: Top 9 Software Outsourcing Mistakes 17/439 - 11 Oct 2021

10 Myths About Low-End Project Management Software 16/340

10 Myths About Low-End Project Management Software 16/340 - 10 Nov 2022

Poor Code Indicators and How to Improve Your Code? 16/231

Poor Code Indicators and How to Improve Your Code? 16/231 - 01 Mar 2023

Bug Prioritization - What are the 5 levels of priority? 16/234

Bug Prioritization - What are the 5 levels of priority? 16/234 - 19 Oct 2021

Is gold plating good or bad in project management? 15/816

Is gold plating good or bad in project management? 15/816 - 19 Apr 2021

7 Most Common Time-Wasters For Software Development 14/556

7 Most Common Time-Wasters For Software Development 14/556 - 26 Sep 2024

Successful Project Management Techniques You Need to Look Out For 14/401

Successful Project Management Techniques You Need to Look Out For 14/401 - 06 Jun 2022

HEIJUNKA: The art of leveling production 13/552

HEIJUNKA: The art of leveling production 13/552 - 08 Oct 2022

KPI - The New Leadership 12/602

KPI - The New Leadership 12/602 - 31 Oct 2021

Tips to Fail Fast With Outsourcing 12/392

Tips to Fail Fast With Outsourcing 12/392 - 19 Sep 2022

Jidoka in Software Development and Odoo ERP/MRP 12/526

Jidoka in Software Development and Odoo ERP/MRP 12/526 - 10 Dec 2023

Pain points of User Acceptance Testing (UAT) 11/452

Pain points of User Acceptance Testing (UAT) 11/452 - 07 Dec 2023

The Myths Of Requirements 10/256

The Myths Of Requirements 10/256 - 12 Mar 2022

The u-Japan concept 10/296

The u-Japan concept 10/296 - 01 Jan 2023

How To Use Poka-Yoke (Mistake Proofing) Technique To Improve Software Quality 10/647

How To Use Poka-Yoke (Mistake Proofing) Technique To Improve Software Quality 10/647 - 28 Dec 2021

8 types of pricing models in software development outsourcing 10/437

8 types of pricing models in software development outsourcing 10/437 - 17 Feb 2022

Prioritizing Software Requirements with Kano Analysis 10/304

Prioritizing Software Requirements with Kano Analysis 10/304 - 10 Nov 2021

Automated QA Outsourcing – Hire a Professional Software Testing Team 9/557

Automated QA Outsourcing – Hire a Professional Software Testing Team 9/557 - 11 Jan 2024

What are the Benefits and Limitations of Augmented Intelligence? 9/477

What are the Benefits and Limitations of Augmented Intelligence? 9/477 - 09 Sep 2024

How AI Rewriting Can Improve Your Content’s SEO Performance 9/188

How AI Rewriting Can Improve Your Content’s SEO Performance 9/188 - 05 Jan 2024

Easy ASANA tips & tricks for you and your team 9/200

Easy ASANA tips & tricks for you and your team 9/200 - 12 Mar 2024

How do you create FOMO in software prospects? 9/167

How do you create FOMO in software prospects? 9/167 - 01 Oct 2020

Handling tight project deadlines as a business analyst 7/331

Handling tight project deadlines as a business analyst 7/331 - 03 Nov 2022

Questions and answers about Kano Model 7/864

Questions and answers about Kano Model 7/864 - 01 Jun 2020

Japan Business Review (JBR) 7/330

Japan Business Review (JBR) 7/330 - 06 Nov 2019

How to Access Software Project Size? 6/249

How to Access Software Project Size? 6/249 - 14 Mar 2024

Why should you opt for software localization from a professional agency? 6/140

Why should you opt for software localization from a professional agency? 6/140 - 26 Dec 2023

Improving Meeting Effectiveness Through the Six Thinking Hats 5/253

Improving Meeting Effectiveness Through the Six Thinking Hats 5/253 - 02 Apr 2022

Productivity vs. Efficiency – What Are the Differences? 4/212

Productivity vs. Efficiency – What Are the Differences? 4/212 - 12 Sep 2024

Be Water, My Friend: Fluidity, Flow & Going With the Flow 3/169

Be Water, My Friend: Fluidity, Flow & Going With the Flow 3/169

What are the 5 Whys concept?

Five whys (5 whys) is a problem-solving method that explores the underlying cause-and-effect of particular problems. The primary goal is to determine the root cause of a defect or a problem by successively asking the question “Why?”.

Origin of 5 Whys

The 5 Whys method is part of the Toyota Production System. Developed by Sakichi Toyoda, a Japanese inventor and industrialist, the technique became an integral part of the Lean philosophy.

“The basis of Toyota’s scientific approach is to ask why five times whenever we find a problem … By repeating why five times, the nature of the problem as well as its solution becomes clear.“ Taiichi Ohno

One of the key factors for successful implementation of the technique is to make an informed decision. This means that the decision-making process should be based on an insightful understanding of what is actually happening on the work floor.

In other words, the root cause analysis process should include people with practical experience. Logically, they can give you the most valuable information regarding any problem that appears in their area of expertise.

Click on each picture to learn more about the 5 Whys

How to Get Started with 5 Whys

The 5 Whys technique may help you achieve continuous improvement at any level of your organization. Here are some basics steps you need to follow.

Form a team

Try to assemble a team of people from different departments. Each representative has to be familiar with the process that is going to be investigated.

By forming a cross-functional team, you are going to receive unique points of view.

This will help you collect enough information to make an informed decision. Be aware that this is not an individual task, and it needs to be executed by the team.

Define the problem

Discuss the problem with the team and make a clear problem statement. It will help you define the scope of the issue you are going to investigate.

This is important because investigating a wide scope problem may be a time-consuming exercise with blurred boundaries. Try to be as focused as possible to find an effective solution in the end.

Ask Why

Empower one person to facilitate the whole process. This team leader will ask the questions and try to keep the team focused. The answers should be based on facts and real data, rather than on emotional opinions.

The facilitator should ask “Why” as many times as needed until the team can identify the root cause of the initial problem.

Advice 1. Don’t ask too many Whys. If you keep going, you may end up receiving tons of unreasonable suggestions and complaints, which is not the purpose. Focus on finding the root cause.

Advice 2. Sometimes there could be more than one root cause. In these cases, the 5 Whys analysis will look more like a matrix with different branches. This may even help you detect and eliminate organizational issues that have permanent negative effects on the overall performance.

Take Action

After the team detects the root cause(s), it is time to take corrective actions. All members should be involved in a discussion to find and apply the best solution that will protect your process from recurring problems.

When the decision is made, one of the team members should be responsible for applying the right actions and observing the whole process.

After a certain period of time, the team needs to meet again and check if their actions actually had a positive impact. If not, the process should be repeated.

In the end, the case should be documented and sent across the organization. Sharing this information will give an insightful overview of different kinds of problems a team may face and how those problems can be eliminated.

Example: 5 Whys for analyzing bug reports

Wrapping-Up

The 5 Whys technique is a simple and effective tool for solving problems. Its primary goal is to find the exact reason that causes a given problem by asking a sequence of “Why” questions.

- The 5 Whys method helps your team focus on finding the root cause of any problem.

- It encourages each team member to share ideas for continuous improvement, rather than blaming others.

- It gives your team the confidence that it can eliminate any problem and prevent the process from recurring failures.

Link copied!

Link copied!

Recently Updated News

Recently Updated News