3 Steps of problem-solving: The San-Gen-Shugi methodology

Last updated: October 21, 2025 Read in fullscreen view

- 02 Nov 2023

Unlocking Success with The Amoeba Management Model: Key Lessons, Pros & Cons, and Finding the Perfect Fit 275/889

Unlocking Success with The Amoeba Management Model: Key Lessons, Pros & Cons, and Finding the Perfect Fit 275/889 - 10 Nov 2021

5S methodology - the SECRET to Japanese SUCCESS 160/1833

5S methodology - the SECRET to Japanese SUCCESS 160/1833 - 09 Sep 2022

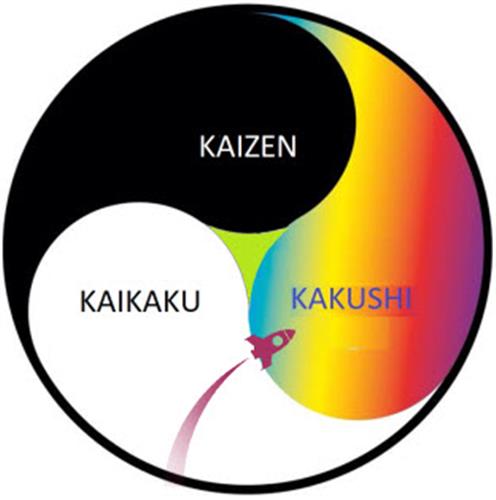

Kaizen, Kaikaku and Kakushin – what’s the difference? 156/3081

Kaizen, Kaikaku and Kakushin – what’s the difference? 156/3081 - 24 Nov 2022

Genba Genbutsu Genjitsu (3Gs), (Go to the Genba & see for yourself!) 136/3058

Genba Genbutsu Genjitsu (3Gs), (Go to the Genba & see for yourself!) 136/3058 - 01 Dec 2023

What is Amoeba Management? 108/1042

What is Amoeba Management? 108/1042 - 01 Apr 2022

Ishikawa (fishbone) diagram in software project management 56/3145

Ishikawa (fishbone) diagram in software project management 56/3145 - 13 Oct 2021

Outsourcing Software Development: MVP, Proof of Concept (POC) and Prototyping. Which is better? 40/486

Outsourcing Software Development: MVP, Proof of Concept (POC) and Prototyping. Which is better? 40/486 - 18 Oct 2020

How to use the "Knowns" and "Unknowns" technique to manage assumptions 38/1089

How to use the "Knowns" and "Unknowns" technique to manage assumptions 38/1089 - 17 Mar 2023

Reduce waste in software development with 3M model: Muda, Mura, Muri 36/960

Reduce waste in software development with 3M model: Muda, Mura, Muri 36/960 - 09 Sep 2022

What is 5 Whys (Five Whys)? 34/970

What is 5 Whys (Five Whys)? 34/970 - 12 Dec 2024

Danshari: A Japanese Minimalist Philosophy for Cleaner Code and Leaner IT Operations 33/97

Danshari: A Japanese Minimalist Philosophy for Cleaner Code and Leaner IT Operations 33/97 - 29 Jan 2026

Honne and Tatemae: Why Do Japanese People Seem Excessively Polite and Indirect? 31/40

Honne and Tatemae: Why Do Japanese People Seem Excessively Polite and Indirect? 31/40 - 12 Oct 2022

14 Common Reasons Software Projects Fail (And How To Avoid Them) 31/567

14 Common Reasons Software Projects Fail (And How To Avoid Them) 31/567 - 19 Oct 2021

Software development life cycles 29/701

Software development life cycles 29/701 - 29 Aug 2022

Difference between Kaizen and Innovation 29/910

Difference between Kaizen and Innovation 29/910 - 03 Jan 2024

What is the Ringi process? 29/974

What is the Ringi process? 29/974 - 04 Mar 2024

Tree Ring Management: Take the Long Term View and Grow Your Business Slowly 29/444

Tree Ring Management: Take the Long Term View and Grow Your Business Slowly 29/444 - 27 Aug 2022

Kaizen - Culture of Continuous Improvement and Lean Thinking 28/824

Kaizen - Culture of Continuous Improvement and Lean Thinking 28/824 - 01 Mar 2022

The Toyota Way Management Principles 28/784

The Toyota Way Management Principles 28/784 - 05 Feb 2024

Ego and Attachment: Simplify Your Life Today 26/275

Ego and Attachment: Simplify Your Life Today 26/275 - 01 Oct 2020

Fail fast, learn faster with Agile methodology 24/1047

Fail fast, learn faster with Agile methodology 24/1047 - 14 Oct 2021

Advantages and Disadvantages of Time and Material Contract (T&M) 22/864

Advantages and Disadvantages of Time and Material Contract (T&M) 22/864 - 02 Feb 2022

Yokoten: Best Practice Sharing from a success 22/1374

Yokoten: Best Practice Sharing from a success 22/1374 - 21 Sep 2023

Abraham Wald and the Missing Bullet Holes 22/666

Abraham Wald and the Missing Bullet Holes 22/666 - 13 Jul 2022

Applying the business mantra "HORENSO" to Achieve 360-degree Communication 22/921

Applying the business mantra "HORENSO" to Achieve 360-degree Communication 22/921 - 15 Apr 2022

Total Quality Management (TQM) - Japanese-style management approach to quality improvement. 22/695

Total Quality Management (TQM) - Japanese-style management approach to quality improvement. 22/695 - 07 Mar 2023

Japan’s Unusual Farming Strategy: Renting Land and Leaving It Fallow for 5 Years — Here’s the Truth… 21/80

Japan’s Unusual Farming Strategy: Renting Land and Leaving It Fallow for 5 Years — Here’s the Truth… 21/80 - 18 Aug 2022

What are the consequences of poor requirements with software development projects? 20/274

What are the consequences of poor requirements with software development projects? 20/274 - 13 Dec 2020

Move fast, fail fast, fail-safe 20/323

Move fast, fail fast, fail-safe 20/323 - 06 Feb 2021

Why fail fast and learn fast? 19/450

Why fail fast and learn fast? 19/450 - 15 Jul 2022

Hansei Methodology: Continuously Engaging People in Improvement 18/707

Hansei Methodology: Continuously Engaging People in Improvement 18/707 - 23 Sep 2021

INFOGRAPHIC: Top 9 Software Outsourcing Mistakes 17/439

INFOGRAPHIC: Top 9 Software Outsourcing Mistakes 17/439 - 04 Oct 2021

Product Validation: The Key to Developing the Best Product Possible 17/320

Product Validation: The Key to Developing the Best Product Possible 17/320 - 05 Sep 2023

The Cold Start Problem: How to Start and Scale Network Effects 17/203

The Cold Start Problem: How to Start and Scale Network Effects 17/203 - 07 Oct 2025

Case Study: Using the “Messaging House” Framework to Build a Digital Transformation Roadmap 17/86

Case Study: Using the “Messaging House” Framework to Build a Digital Transformation Roadmap 17/86 - 01 Mar 2023

Bug Prioritization - What are the 5 levels of priority? 16/234

Bug Prioritization - What are the 5 levels of priority? 16/234 - 10 Nov 2022

Poor Code Indicators and How to Improve Your Code? 16/231

Poor Code Indicators and How to Improve Your Code? 16/231 - 31 Aug 2022

What are the best practices for software contract negotiations? 16/260

What are the best practices for software contract negotiations? 16/260 - 19 Oct 2021

Is gold plating good or bad in project management? 15/816

Is gold plating good or bad in project management? 15/816 - 05 Mar 2021

How do you minimize risks when you outsource software development? 15/335

How do you minimize risks when you outsource software development? 15/335 - 19 Apr 2021

7 Most Common Time-Wasters For Software Development 14/556

7 Most Common Time-Wasters For Software Development 14/556 - 26 Sep 2024

Successful Project Management Techniques You Need to Look Out For 14/401

Successful Project Management Techniques You Need to Look Out For 14/401 - 06 Jun 2022

HEIJUNKA: The art of leveling production 13/552

HEIJUNKA: The art of leveling production 13/552 - 28 Jul 2022

POC, Prototypes, Pilots and MVP: What Are the Differences? 13/697

POC, Prototypes, Pilots and MVP: What Are the Differences? 13/697 - 28 Oct 2022

Build Operate Transfer (B.O.T) Model in Software Outsourcing 12/405

Build Operate Transfer (B.O.T) Model in Software Outsourcing 12/405 - 08 Oct 2022

KPI - The New Leadership 12/602

KPI - The New Leadership 12/602 - 31 Oct 2021

Tips to Fail Fast With Outsourcing 12/392

Tips to Fail Fast With Outsourcing 12/392 - 19 Sep 2022

Jidoka in Software Development and Odoo ERP/MRP 12/526

Jidoka in Software Development and Odoo ERP/MRP 12/526 - 10 Dec 2023

Pain points of User Acceptance Testing (UAT) 11/452

Pain points of User Acceptance Testing (UAT) 11/452 - 04 Oct 2022

Which ERP implementation strategy is right for your business? 11/313

Which ERP implementation strategy is right for your business? 11/313 - 01 Jan 2023

How To Use Poka-Yoke (Mistake Proofing) Technique To Improve Software Quality 10/647

How To Use Poka-Yoke (Mistake Proofing) Technique To Improve Software Quality 10/647 - 12 Mar 2022

The u-Japan concept 10/296

The u-Japan concept 10/296 - 28 Dec 2021

8 types of pricing models in software development outsourcing 10/437

8 types of pricing models in software development outsourcing 10/437 - 17 Feb 2022

Prioritizing Software Requirements with Kano Analysis 10/304

Prioritizing Software Requirements with Kano Analysis 10/304 - 12 Dec 2021

Zero Sum Games Agile vs. Waterfall Project Management Methods 10/409

Zero Sum Games Agile vs. Waterfall Project Management Methods 10/409 - 18 Jul 2021

How To Ramp Up An Offshore Software Development Team Quickly 9/593

How To Ramp Up An Offshore Software Development Team Quickly 9/593 - 11 Jan 2024

What are the Benefits and Limitations of Augmented Intelligence? 9/477

What are the Benefits and Limitations of Augmented Intelligence? 9/477 - 03 Feb 2024

"Kham Nhẫn" in Business: A Guide to Patience and Resilience 9/165

"Kham Nhẫn" in Business: A Guide to Patience and Resilience 9/165 - 09 Sep 2024

How AI Rewriting Can Improve Your Content’s SEO Performance 9/188

How AI Rewriting Can Improve Your Content’s SEO Performance 9/188 - 05 Jan 2024

Easy ASANA tips & tricks for you and your team 9/200

Easy ASANA tips & tricks for you and your team 9/200 - 12 Mar 2024

How do you create FOMO in software prospects? 9/167

How do you create FOMO in software prospects? 9/167 - 06 Mar 2024

[SemRush] What Are LSI Keywords & Why They Don‘t Matter 7/176

[SemRush] What Are LSI Keywords & Why They Don‘t Matter 7/176 - 01 Jun 2020

Japan Business Review (JBR) 7/330

Japan Business Review (JBR) 7/330 - 06 Nov 2019

How to Access Software Project Size? 6/249

How to Access Software Project Size? 6/249 - 12 Aug 2024

Understanding Google Analytics in Mumbai: A Beginner's Guide 6/99

Understanding Google Analytics in Mumbai: A Beginner's Guide 6/99 - 14 Mar 2024

Why should you opt for software localization from a professional agency? 6/140

Why should you opt for software localization from a professional agency? 6/140 - 26 Dec 2023

Improving Meeting Effectiveness Through the Six Thinking Hats 5/253

Improving Meeting Effectiveness Through the Six Thinking Hats 5/253 - 01 Dec 2023

Laws of Project Management 5/302

Laws of Project Management 5/302 - 15 Aug 2025

Quantum Technology: Global Challenges and Opportunities for Innovators 4/100

Quantum Technology: Global Challenges and Opportunities for Innovators 4/100 - 12 Sep 2024

Be Water, My Friend: Fluidity, Flow & Going With the Flow 3/169

Be Water, My Friend: Fluidity, Flow & Going With the Flow 3/169 - 01 May 2024

Warren Buffett’s Golden Rule for Digital Transformation: Avoiding Tech Overload 3/205

Warren Buffett’s Golden Rule for Digital Transformation: Avoiding Tech Overload 3/205

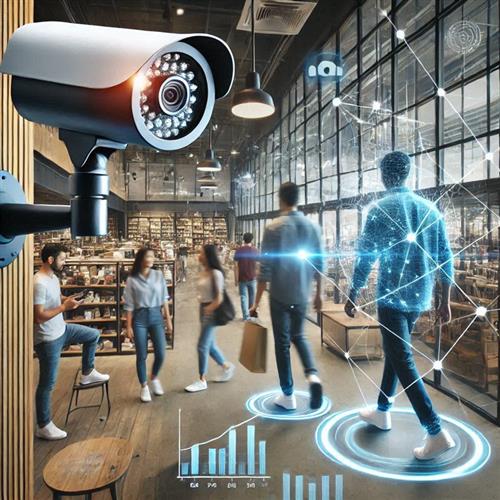

San Gen Shugi: The "3 Realities" Key to Root Cause Problem-Solving and Achieving Zero Defects

San Gen Shugi (三現主義), or the "Three Realities Principle," is a core philosophy developed within the Toyota Production System (TPS). It serves as a guiding principle that helps organizations not only solve problems quickly but also prevent their recurrence, aiming for the quality goal of Zero Defects (無欠陥 / Mukeppan, or No Flaws/Mistakes).

In the modern business environment, problem-solving based on assumptions, paper reports, or indirect information often leads to superficial and costly fixes. San Gen Shugi was established to eliminate this issue, requiring leaders and employees to go, see, and confirm the reality on the ground.

1. The Essence of the San Gen Shugi Methodology: The Three "Realities"

San Gen Shugi comprises three core elements (or the "3 Gen") that are fundamental to all analysis and improvement activities:

| Element | Japanese Term | Meaning | Action Principle |

| Genba | 現場 | The Actual Place | Go to the location where the problem occurred (factory floor, office, customer complaint site) to observe directly. |

| Genbutsu | 現物 | The Actual Thing | Observe the physical object, part, machine, defective product, or the actual process related to the problem. |

| Genjitsu | 現実 | The Actual Facts/Reality | Base conclusions on data, evidence, and on-site observations, not on assumptions or aggregated reports. |

The core principle is Genchi Genbutsu – "Go and See for Yourself" – the combination of Genba (Go to the actual place) and Genbutsu (Check the actual thing) to grasp Genjitsu (The actual facts).

2. Application in Problem-Solving (3 Steps)

To apply San Gen Shugi to the problem-solving process, you must follow three basic steps, ensuring every solution is based on reality at the source:

Step 1: Identify the Problem at Genba (The Actual Place)

- Action: Instead of just reading a report, immediately go to the location where the problem occurred (Genba).

- Goal: Understand the context, scope, and impact of the problem. Record the current situation through direct observation and discuss it with those involved.

Step 2: Analyze using Genbutsu and Genjitsu (Actual Thing and Actual Facts)

- Action: Inspect the Genbutsu (defective product, broken machine, incorrect document) and collect Genjitsu (data, metrics, specific evidence) at the site.

- Goal: Compare "what happened" (reality) with "what should have happened" (standard). This analysis is the basis for finding the Root Cause, often through tools like the 5 Whys method.

Step 3: Implement Action and Prevent Recurrence

- Action: Based on the Genbutsu/Genjitsu evidence collected, implement immediate corrective actions, followed by permanent solutions.

- Goal: Ensure the solution addresses the root cause found at Genba, not just the symptom. This prevents the problem from recurring.

3. San Gen Shugi and the Zero Defects Goal

The Zero Defects goal is a commitment to quality where errors are prevented from the outset. San Gen Shugi is the perfect methodology to support this goal because it:

- Eliminates Assumptions: The Go and See principle ensures that management makes decisions based on reality, not indirect information or guesses, thereby minimizing the chance of implementing wrong or ineffective solutions.

- Uncovers Root Causes: Directly observing the Genbutsu and verifying the Genjitsu forces the problem solver to find the deepest cause, leading to the design of robust prevention measures (Poka-Yoke) instead of just temporary fixes.

- Fosters a Culture of Continuous Improvement (Kaizen): San Gen Shugi encourages a culture where everyone proactively seeks out and solves problems at the source, continuously improving processes and moving closer to the ideal of absolute quality.

Conclusion

San Gen Shugi is more than just a problem-solving tool; it is a leadership mindset that demands a commitment to reality. By applying the 3 Gen – Go to the actual place (Genba), Inspect the actual thing (Genbutsu), Confirm the actual facts (Genjitsu) – businesses can ensure problems are solved thoroughly, drive superior quality, and move closer to the Zero Defects ideal.

Link copied!

Link copied!

Recently Updated News

Recently Updated News